KBM: HIGHLY DYNAMIC FRAMELESS TORQUE MOTORS

The frameless kit motor of the KBM™ series is Kollmorgen's latest innovation in rotary direct drives. The KBM kit motor offers engineers in mechanical and plant engineering a wide range of solutions to realize applications with a maximum of flexibility, power density, dynamics and service life. The kit motor of the KBM series is also extremely easy to fit and install. Hall effect sensors are optionally available ex works. The KBM direct drives are available in every size with several winding variants; the optimized insulation properties allow the use in a wide voltage range up to 680Vdc.

With eight flange sizes from 40 to 260mm and several overall lengths each, an enormous spectrum of applications with holding torques from 0.18 Nm to 180 Nm can be covered. The sizes are selected in such a way that the torque ranges of two adjacent flange sizes overlap and thus an ideal ratio between load and rotor inertia can be found.

For the KBM frameless torque motor series, a clever combination of standard elements was chosen, resulting in short delivery times and an excellent price-performance ratio.

The most important features of KBM frameless torque motors are:

- 14 sizes (60mm to 782mm OD), each with 3 or 4 different lengths

- continuous holding torque from 0.5 Nm to 3,500 Nm

- potted stator winding

- max. internal winding temperature 155°C

- thermal sensor in the winding (PTC)

- bonded rotor magnets

- customer-specific frameless torque motor versions possible

Suitable Servodrives with CANopen, EtherCAT or ProfiNet can be found here:

- 3-phase 400 / 480Vac supply: Servo Controller Kollmorgen AKD / AKD2G

- 3-phase/1-phase 110Vac to 230Vac supply: Servo Controller Copley Xenus / Kollmorgen AKD / AKD2G

- DC-supply 12Vdc / 24Vdc / 48Vdc / 96Vdc / 180Vdc: Servo Controller Copley Argus / M-Series / IES / Accelnet Plus / Accelus and Kollmorgen AKD / AKD2G

| model data sheet  |

drawing without Halls  |

drawing with Halls  |

peak torque Nm |

continuous torque Nm |

Km Nm/W^1/2 |

poles | dimensions OD / ID mm |

length stator mm |

l total without / with Halls mm |

mass without / with Halls kg |

|

KBM-10X01 KBM-10X02 KBM-10X03 KBM-10X04 |

Zeichnung KBM-10 ohne Halls |

Zeichnung KBMS-10 mit Halls |

1.17 | 0.487 | 0.065 | 6 | 60.0 / 16.0 | 46.0 | 46.0 / 53.31 | 0.379 / 0.425 |

| 2.33 | 0.876 | 0.107 | 65.0 | 65.0 / 72.19 | 0658 / 0.703 | |||||

| 3.46 | 1.16 | 0.136 | 84.0 | 84.0 / 91.06 | 0.943 / 0.990 | |||||

| 5.46 | 1.45 | 0.168 | 103.0 | 103.0 / 109.94 | 1.22 / 1.26 | |||||

|

KBM-14X01 KBM-14X02 KBM-14X03 |

Zeichnung KBM-14 ohne Halls |

Zeichnung KBMS-14 mit Halls |

3.28 | 1.22 | 0.144 | 8 | 75.0 / 20.0 | 58.0 | 58.0 / 65.33 | 0.898 / 1.0 |

| 6.67 | 2.08 | 0.225 | 89.0 | 89.0 / 96.22 | 1.59 / 1.68 | |||||

| 10.1 | 2.82 | 0.279 | 120.0 | 120.0 / 127.1 | 2.98 / 3.08 | |||||

|

KBM-17X01 KBM-17X02 KBM-17X03 KBM-17X04 |

Zeichnung KBM-17 ohne Halls |

Zeichnung KBMS-17 mit Halls |

5.95 | 2.08> | 0.227 | 10 | 85.0 / 30.0 | 57.8 | 57.8 / 65.10 | 1.05 /1.16 |

| 12.2 | 3.58 | 0.359 | 86.8 | 86.8 / 93.98 | 1.87 / 1.97 | |||||

| 18.5 | 4.89 | 0.461 | 115.80 | 115.8 / 122.86 | 2.65 / 2.76 | |||||

| 23.7 | 6.2 | 0.544 | 144.8 | 144.8 / 151.74 | 3.62 / 3.72 | |||||

|

KBM-25X01 KBM-25X02 KBM-25X03 KBM-25X04 |

Zeichnung KBM-25 ohne Halls |

Zeichnung KBMS-25 mit Halls |

14.4 | 4.9 | 0.452 | 10 | 110.0 / 50.0 | 62.70 | 62.70 / 70.04 | 1.79 / 2.02 |

| 29.4 | 8.7 | 0.729 | 93.70 | 93.70 / 100.93 | 3.27 / 3.50 | |||||

| 42.2 | 11.9 | 0.939 | 124.70 | 124.70 / 131.81 | 4.72 / 4.90 | |||||

| 54.4 | 14.8 | 1.11 | 155.70 | 155.70 / 162.70 | 6.17 / 6.35 | |||||

|

KBM-35X01 KBM-35X02 KBM-35X03 KBM-35X04 |

Zeichnung KBM-35 ohne Halls |

Zeichnung KBMS-35 mit Halls |

40.9 | 12.6 | 0.954 | 10 | 140.0 / 65.0 | 83.74 | 83.74 / 90.92 | 4.68 / 5.17 |

| 58.8 | 17.3 | 1.24 | 108.74 | 108.74 / 115.79 | 6.76 / 7.21 | |||||

| 76.1 | 21.8 | 1.51 | 133.74 | 133.74 / 140.65 | 8.80 / 9.34 | |||||

| 92.3 | 25.6 | 1.71 | 158.74 | 158.74 / 165.52 | 10.9 / 11.3 | |||||

|

KBM-43X01 KBM-43X02 KBM-43X03 |

Zeichnung KBM-43 ohne Halls |

Zeichnung KBMS-43 mit Halls |

18.0 | 6.1 | 0.580 | 16 | 159.82 / 76.25 | 11.43 | 36.07 / 44.07 | 2.26 / 2.66 |

| 34.6 | 11.6 | 1.00 | 22.86 | 47.50 / 55.50 | 3.49 / 3.89 | |||||

| 64.5 | 21.0 | 1.65 | 45.72 | 70.36 / 78.36 | 5.96 / 6.39 | |||||

|

KBM-45X01 KBM-45X02 KBM-45X03 |

Zeichnung KBM-45 ohne Halls |

Zeichnung KBMS-45 mit Halls |

119 | 30.7 | 2.16 | 10 | 190.0 / 85.0 | 107.6 | 107.6 / 114.29 | 12.2 / 13.2 |

| 170 | 43.7 | 2.80 | 141.06 | 141.06 / 148.17 | 17.5 / 18.5 | |||||

| 218 | 54.6 | 3.36 | 175.05 | 175.05 / 182.05 | 23.1 / 24.2 | |||||

|

KBM-57X01 KBM-57X02 KBM-57X03 |

Zeichnung KBM-57 ohne Halls |

Zeichnung KBMS-57 mit Halls |

46.1 | 18.8 | 1.49 | 24 | 202.95 / 104.14 | 20.32 | 44.96 / 52.96 | 4.54 / 5.31 |

| 115 | 33.5 | 2.51 | 40.64 | 65.28 / 73.28 | 7.89 / 8.62 | |||||

| 218 | 60.0 | 3.71 | 81.79 | 106.43 / 114.43 | 14.5 / 15.4 | |||||

|

KBM-60X01 KBM-60X02 KBM-60X03 |

Zeichnung KBM-60 ohne Halls |

Zeichnung KBMS-60 mit Halls |

127 | 53.9 | 3.44 | 38 | 229.90 / 105.02 | 48.11 | 103.74 / 106.91 | 13.2 / 15.3 |

| 255 | 108 | 5.78 | 97.71 | 153.34 / 156.51 | 25.2 / 27.9 | |||||

| 393 | 154 | 7.46 | 147.32 | 202.95 / 206.12 | 37.2 / 39.8 | |||||

|

KBM-79X01 KBM-79X02 KBM-79X03 |

Zeichnung KBM-79 mit Halls |

Zeichnung KBMS-79 mit Halls |

152 | 43.5 | 2.89 | 32 | 259.66 / 152.45 | 31.75 | 58.43 / 66.29 | 9.2 / 10.7 |

| 319 | 79.6 | 4.81 | 63.50 | 90.18 / 98.04 | 16.9 / 18.4 | |||||

| 637 | 143 | 7.29 | 127.00 | 153.68 / 161.54 | 32.1 / 33.5 | |||||

|

KBM-88X01 KBM-88X02 KBM-88X03 |

Zeichnung KBM-88 ohne Halls |

Zeichnung KBMS-88 mit Halls |

414 | 205 | 10.3 | 46 | 331.50 / 154.98 | 67.56 | 132.58 / 135.63 | 37.6 / 42.6 |

| 789 | 385 | 16.3 | 136.65 | 201.67 / 204.72 | 72.6 / 77.6 | |||||

| 1.200 | 538 | 20.6 | 205.74 | 270.76 / 273.81 | 106 / 111 | |||||

|

KBM-118X01 KBM-118X02 KBM-118X03 KBM-118X04 |

Zeichnung KBM-118 ohne Halls |

Zeichnung KBMS-118 mit Halls |

994 | 325 | 11.8 | 38 | 361.20 / 260.29 | 101.60 | 145.42 / 149.86 | 37.1 / 39.2 |

| 1.451 | 446 | 14.6 | 152.40 | 196.22 / 200.66 | 53.5 / 56.2 | |||||

| 1.932 | 560 | 17.1 | 203.20 | 247.02 / 251.46 | 71.7 / 73.9 | |||||

| 2.400 | 672 | 19.4 | 254.00 | 297.82 / 302.26 | 88.5 / 90.7 | |||||

|

KBM-163X01 KBM-163X02 KBM-163X03 |

Zeichnung KBM-163 ohne Halls |

Zeichnung KBMS-163 mit Halls |

1.966 | 776 | 25.6 | 56 | 537.16/ 333.16 Flansch 605.0 |

142.54 | 142.54 | 90.7 / 96.2 |

| 2.915 | 1.090 | 32.5 | 193.34 | 193.34 | 131 / 136 | |||||

| 3.932 | 1.376 | 38.2 | 244.14 | 244.14 | 161 / 166 | |||||

|

KBM-260X01 KBM-260X02 KBM-260X03 |

Zeichnung KBM-260 ohne Halls |

Zeichnung KBMS-260 mit Halls |

6.494 | 1.932 | 47.1 | 58 | 781.89/ 597.50 Flansch 850.0 |

172.62 | 172.62 | 170 / 177 |

| 9.742 | 2.706 | 59.8 | 237.39 | 237.39 | 249 / 257 | |||||

| 12.812 | 3.445 | 70.4 | 302.16 | 302.16 | 329 / 336 |

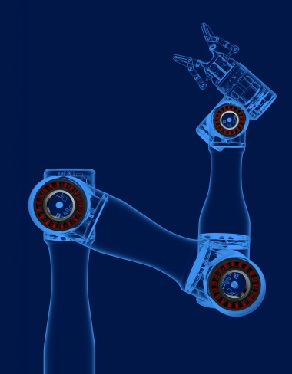

TBM2G: Frameless direct drive torque motors with hollow shaft for low voltages 48Vdc / 24Vdc and below - designed for robotic joints

Kollmorgen introduces the new TBM2G series of frameless torque motors with hollow shaft specifically designed to optimise the design of collaborative and medical robots, aerospace and defence robots and other robots. The TBM2G servo motors are the evolution of the existing TBM and KBM motor series according to feedback from our customers - the TBM2G motor series represents the result of several years of research and development and testing and, with its hollow shaft and optimised windings, simultaneously enables optimal performance in a lighter, more compact package and high performance torque through an extremely compact electromagnetic design. These next-generation torque motors enable the design of robots with lower joint weight, higher load capacity, improved energy efficiency, reduced thermal input and more dynamic movements.

The TBM2G are ideally suited for battery-powered and mobile applications such as autonomous mobile robots (AMR) and automated guided vehicles (AGV). The seven frame sizes correspond to the sizes used in embedded applications such as collaborative and surgical robots. The standard sizing is optimised for combination with commercially available shaft gearboxes. The large inner diameter through hole of the TBM2G hollow shaft motors can be used for encoders, cables, hoses, shafts, tools, etc.

The main features of the TBM2G torque motor series are:

- seven sizes from 50 to 119mm outer diameter

- hollow shaft from 24.75 to 57.5mm

- optimised standard windings for 48V (DC) / 24V (DC) and below

- optimised windings for speed and torque requirements in collaborative robot applications weighing 3.5 and 15 kilograms and more

- multiple standard thermal sensor options to suit the most popular drives on the cobot market

- low cogging torque for smooth operation

- optional integrated Hall sensors that do not extend the motor length

- designed to perform well without exceeding 85 °C, but at the same time capable of delivering full

capable of maintaining full power at winding temperatures up to 155 °C on a continuous basis - corrosion-resistant stainless steel rotors with hollow shaft

- epoxy-coated ring magnet (neodymium, NdFeB)

- optional: connectors and customised versions (Kollmorgen Co-Engineering)

Suitable Servodrives also for direct integration into the robotic joint with CANopen or EtherCAT can be found here:

- DC-supply 12Vdc / 24Vdc / 48Vdc / 96Vdc / 180Vdc: Servo Controller Copley Argus / M-Series / IES / Accelnet Plus / Accelus and Kollmorgen AKD / AKD2G

| Model | cont.- holding torque Nm |

nominal speed rpm |

nominal power kW |

motor constant Nm/√W |

size OD /ID mm |

length mm |

| TBM2G-05008 | 0.27 | 8,000 | 0.204 | 0.061 | 50 / 24.75 | 20.64 |

| TBM2G-05013 | 0.38 | 8,000 | 0.271 | 0.083 | 25.14 | |

| TBM2G-05026 | 0.64 | 6,700 | 0.368 | 0.128 | 38.74 | |

| TBM2G-06008 | 0.45 | 8,000 | 0.329 | 0.087 | 60 / 30 | 17.58 |

| TBM2G-06013 | 0.60 | 8,000 | 0.415 | 0.114 | 22.08 | |

| TBM2G-06026 | 0.96 | 4,200 | 0.366 | 0.176 | 35.68 | |

| TBM2G-06808 | 0.63 | 8,000 | 0.467 | 0.119 | 68 / 34 | 18.58 |

| TBM2G-06813 | 0.86 | 6,600 | 0.538 | 0.157 | 23.08 | |

| TBM2G-06826 | 1.54 | 3,300 | 0.506 | 0.251 | 36.68 | |

| TBM2G-07608 | 0.89 | 8,000 | 0.588 | 0.157 | 76 / 38 | 18.51 |

| TBM2G-07613 | 1.13 | 6,600 | 0.605 | 0.193 | 23.01 | |

| TBM2G-07626 | 2.06 | 2,900 | 0.560 | 0.324 | 36.61 | |

| TBM2G-08508 | 1.21 | 8,000 | 0.741 | 0.203 | 85 / 42.5 | 19.58 |

| TBM2G-08513 | 1.65 | 5,200 | 0.725 | 0.271 | 24.08 | |

| TBM2G-08526 | 2.69 | 2,700 | 0.670 | 0.419 | 37.68 | |

| TBM2G-09408 | 1.58 | 8,000 | 0.86 | 0.263 | 94 / 47 | 19.93 |

| TBM2G-09413 | 2.05 | 5,800 | 0.87 | 0.331 | 24.43 | |

| TBM2G-09426 | 3.67 | 2,900 | 0.945 | 0.528 | 38.03 | |

| TBM2G-11508 | 1.9 | 5,800 | 0.860 | 0.263 | 115 / 57.5 | 26.2 |

| TBM2G-11513 | 3.04 | 4,900 | 0.969 | 0.464 | 30.7 | |

| TBM2G-11526 | 6.03 | 3,300 | 1.463 | 0.802 | 44.3 |

TBM: Frameless direct drive torque motors for low voltages 24Vdc / 48Vdc / 100Vdc

Kollmorgen's TBM series of frameless torque motors are rotary direct drives without integral bearings, are suitable for low operating voltages of 24Vdc, 48Vdc up to 120Vdc and are integrated directly into the machine; mechanically they use the machine's bearings and the position sensor is not part of the kit torque motor. The standard torque motors offered are characterized by high performance in a compact design with minimum weight and moment of inertia; the standard versions provide a good basis, but can be customized to find the right rotary direct drive for your application. The frameless kit torque motors of the TBM series are used where high performance is required in a small and compact high torque motor with minimum weight and moment of inertia.

The most important features of the TBM torque motor series are:

- several sizes from 60 to 129mm outer diameter

- optimized standard windings for 24Vdc, 48Vdc, 96Vdc

- low cogging torque

- corrosion-resistant stainless steel rotors

- bandaged rotors

- nameplate of the frameless torque motor with laser marking

- RoHS compliant

- CE compliant (at rated voltage)

- optional: customer-specific windings, digital Hall Effect sensors with memory function

Suitable Servodrives for low voltage DC-supply with CANopen or EtherCAT can be found here:

- DC-supply 12Vdc / 24Vdc / 48Vdc / 96Vdc / 180Vdc: Servo Controller Copley Argus / M-Series / IES / Accelnet Plus / Accelus and Kollmorgen AKD / AKD2G

| model | peak torque Nm |

continuous torque Nm |

voltage Vdc |

dimensions OD /ID mm |

lengths mm |

max. speed turns/min |

| TBM(s)60 | 1.37 - 4.53 | 0.41 - 1.16 | 48 | 60.35 / 28.70 | 12.70; 25.40; 50.80 | 4300 |

| TBM(s)76 | 2.86 - 6.89 | 0.99 - 2.39 | 48 | 75.97 / 36.07 | 15.24; 30.73; 46.23 | 4025 |

| TBM(s)129 | 8.07 - 39.4 | 3.12 - 10.3 | 100 | 128.93 / 55.88 | 13.33; 41.28; 54.61 | 2700 |

KinetiMax HPD: brushless external rotor torque motors

The cost-effective torque motors of the KinetiMax High-Power-Density series from our partner Allied Motion are brushless external rotor motors and are supplied as a motor kit consisting of stator and rotor. The customer is responsible for the bearings and sensors in his application, which gives him full design flexibility. The KinetiMax external rotor torque motors are available in 6 sizes, each with 3 different lengths and windings to ensure maximum flexibility and to suit your application. High torque and low cogging make the direct drives suitable for use in robotic applications, AGVs or tools.

The key features of KinetiMax HPD external rotor torque motors are:

- 6 sizes with diameters from 62mm to 125mm

- in each size 3 lengths and 3 winding options

- torque from 0.24Nm to 6.7Nm

- power of up to 1,171W

- low cogging torque

Suitable Servodrives with CANopen or EtherCAT can be found here:

- DC-supply 12Vdc / 24Vdc / 48Vdc / 96Vdc / 180Vdc: Servo Controller Copley Argus / M-Series / IES / Accelnet Plus / Accelus and Kollmorgen AKD / AKD2G

| Model | rotor size outer diameter (mm) |

stator size outer diameter (mm) |

length (mm) | voltage (Vdc) | torque (Nm) | nominal speed (rpm) | current (Arms) | power (W) |

| KM062 | 61.2 | 37.5 | 20.9 | 18 | 0.159 | 5200 | 4.1 | 87 |

| 26.8 | 24 | 0.318 | 3600 | 4.1 | 120 | |||

| 32.8 | 36 | 0.435 | 3300 | 3.8 | 150 | |||

| KM072 | 72.3 | 44.3 | 24.2 | 24 | 0.340 | 4250 | 5.7 | 151 |

| 31.2 | 18 | 0.680 | 2850 | 9.9 | 203 | |||

| 38.2 | 24 | 0.940 | 2500 | 9.1 | 246 | |||

| KM083 | 83.3 | 51.1 | 27.6 | 18 | 0.580 | 3800 | 12.7 | 231 |

| 35.7 | 24 | 1.130 | 2600 | 12.4 | 308 | |||

| 43.7 | 30 | 1.630 | 2150 | 11.9 | 367 | |||

| KM095 | 95.0 | 58.5 | 31.2 | 18 | 0.920 | 3350 | 15.4 | 323 |

| 40.0 | 24 | 1.800 | 2285 | 15.1 | 431 | |||

| 49.1 | 16 | 2.520 | 2000 | 14.1 | 528 | |||

| KM109 | 109.0 | 67.1 | 36.4 | 24 | 1.410 | 3100 | 17.9 | 458 |

| 47.6 | 30 | 2.800 | 2200 | 17.8 | 645 | |||

| 58.5 | 42 | 3.900 | 1900 | 16.6 | 776 | |||

| KM125 | 125.0 | 76.9 | 41.1 | 30 | 2.290 | 3000 | 22.2 | 719 |

| 54.7 | 42 | 4.400 | 2150 | 21.3 | 991 | |||

| 65.5 | 48 | 6.300 | 1800 | 20.3 | 1188 |

KIT TORQUE MOTORS IR (inner rotor), XR (outer rotor) for low voltage 24Vdc/48Vdc

With its frameless kit motors for low voltage, the manufacturer PMW Dynamics presents both internal rotor (IR) and external rotor (XR) servo motors. In principle, these motor kits are are the internal motor designs which are used already in the PMW's own wheel hub motors. The original idea for the kit motors was to give ambitious designers greater flexibility when integrating the motors into the wheel hub and to save both space and costs by eliminating the clutch and other add-on parts. The technically valuable side effect of mounting the motor directly on the drive shaft is the higher system rigidity, which allows a significantly higher inertia mis-match between the motor and load in terms of control technology without any loss of performance.

The kit motors from PMW Dynamics are characterized by particularly short stator lengths, which makes very flat drive designs possible.

As the PMW kit motors are derived from wheel hub motors, the windings are already optimized for operation with batteries, as required for use in mobile robotic and transport systems (AGV), medical systems and other mobile applications. However, other windings are possible in principle.

The most important features of the IR internal rotor motors with hollow shaft are:

- 6 sizes (xx to xxmm OD)

- Continuous holding torque from 0.5 to 11.5 Nm

- Short stator lengths

- Optional thermal sensor in the winding (PTC)

- optional Hall sensors

- Customized designs possible

The most important features of the XR external rotor motors with hollow shaft are:

- tbd sizes (xx to xxmm OD)

- continuous holding torque from tbd to tbd Nm

- short stator lengths

- optional thermal sensor in the winding (PTC)

- optional Hall sensors

- customized designs possible

Suitable Servodrives with CANopen or EtherCAT can be found here:

- DC-supply 12Vdc / 24Vdc / 48Vdc / 96Vdc / 180Vdc: Servo Controller Copley Argus / M-Series / IES / Accelnet Plus / Accelus and Kollmorgen AKD / AKD2G

CARTRIDGE DDR: HOUSED TORQUE MOTORS WITHOUT INTEGRAL BEARING

The torque motors of the CARTRIDGE DDR® series from our partner Kollmorgen are rotary direct drive high pole count servo motors. They combine the advantages of frameless kit motors with those of a finished motor, because the motor is pre-assembled in a housing and the high-resolution encoder is also already installed and adjusted at the factory - but the motor does not have its own bearing. The CARTRIDGE DDR® thus represents a completely new class of direct drive rotary torque motors.

For the customer, this results in extremely simple integration without the usual risk in encoder selection and design; in addition, Cartridge DDR offers defined and measured performance data; a sophisticated packaging concept ensures extremely simple installation in the machine. However, mechanical overdetermination with regard to the bearings is avoided. Not only do they combine the performance advantages of frameless direct drive motors with the simple mounting of housed motors, but they are also available at a significantly lower price than conventional direct drive torque motors and also save money by eliminating mechanical components. Conventional servo systems typically require a number of mechanical components for power transmission, which not only limit the performance and reliability of these systems, but also drive up operating costs. The CARTRIDGE DDR torque motors, on the other hand, do not require mechanical components for power transmission.

The CARTRIDGE DDR® torque motors are UL listed and can be used for applications worldwide.

The advantages of the CARTRIDGE DDR® torque motors are obvious:

- simplified installation (5 minutes) - simply install the motor and connect the cables

- increased machine operating times due to maintenance-free operation

- up to 20 dB less noise due to the omission of the power transmission mechanism

- up to 50 times improved accuracy

- the direct coupling to the load makes maintenance of gears, belts or pulleys unnecessary: no maintenance - no operating costs

- low cogging ensures smooth running at low speed

- higher torque density than conventional direct drive servo motors due to unique electromagnetic design

- improved system response due to eliminated backlash and compatibility

- easy installation and commissioning of the system thanks to preconfigured amplifiers and feedback units

The most important features of CARTRIDGE DDR® torque motors are:

- 5 flange sizes: 108mm, 138mm, 188mm, 246mm and 350mm

- several overall lengths of each flange size

- continuous torque from 4.6Nm to 510Nm

- peak torque from 11Nm to 1.017Nm

- speeds up to 1,500rpm

- sine encoder for absolute position with a maximum resolution of 2,097,152 steps per revolution

- overtemperature protection by built-in thermistor

Suitable Servodrives with CANopen, EtherCAT or ProfiNet can be found here:

- 3-phase 400 / 480Vac supply: Servo Controller Kollmorgen AKD / AKD2G

- 3-phase/1-phase 110Vac to 230Vac supply: Servo Controller Copley Xenus / Kollmorgen AKD / AKD2G

- DC-supply 12Vdc / 24Vdc / 48Vdc / 96Vdc / 180Vdc: Servo Controller Copley Argus / M-Series / IES / Accelnet Plus / Accelus and Kollmorgen AKD / AKD2G

| model | peak torque Nm |

continuous torque (110° increase) Nm |

continuous torque (70° or 80° increase) Nm |

dimensions flange mm |

length mm |

shaft journal machine d x l mm |

max. speed 400V |

max. speed 480V |

| CH041A | 11.3 | 4.5 | 2.9 | 108 | 171 | 32 (33) x 61 | 2500 | 2500 |

| CH042A | 19.0 | 8.2 | 7.2 | 202 | 32 (33) x 92 | 2500 | 2500 | |

| CH043A | 25.3 | 11.1 | 9.7 | 233 | 32 (33) x 123 | 2250 | 2500 | |

| CH044A | 31.6 | 13.9 | 12.4 | 264 | 32 (33) x 154 | 1850 | 2250 | |

| CH051A | 28.0 | 11.7 | 10.2 | 138 | 195 | 45 (46) x 82 | 2100 | 2500 |

| CH052A | 43.5 | 17.0 | 14.8 | 220 | 45 (46) x 107 | 2500 | 2500 | |

| CH053A | 54.1 | 21.0 | 18.3 | 245 | 45 (46) x 132 | 2350 | 2500 | |

| CH054A | 63.8 | 24.9 | 21.8 | 270 | 45 (46) x 157 | 2100 | 2500 | |

| CH061A | 86.8 | 33.8 | 29.4 | 188 | 226 | 71 (72) x 104 | 1600 | 1900 |

| CH062A | 123 | 47.8 | 41.7 | 260 | 71 (72) x 138 | 1650 | 2000 | |

| CH063A | 157 | 61.0 | 53.2 | 294 | 71 (72) x 172 | 1250 | 1500 | |

| CH091A | 120 | 50.2 | 44.7 | 246 | 204 | 60 (70) x 77 | 1200 | 1500 |

| CH092A | 231 | 101 | 90.2 | 252 | 60 (70) x 121 | 700 | 900 | |

| CH093A | 309 | 145 | 129 | 302 | 60 (70) x 157 | 550 | 650 | |

| CH131A | 389 | 188 | 167 | 350 | 231 | 70 (80) x 96 | 400 | 500 |

| CH131B | 396 | 190 | 168 | 800 | 1000 | |||

| CH132A | 806 | 361 | 320 | 300 | 70 (80) x 150 | 200 | 250 | |

| CH132B | 759 | 361 | 320 | 400 | 500 | |||

| CH133A | 1.016 | 504 | 447 | 370 | 70 (80) x 235 | 160 | 200 | |

| CH133B | 1.017 | 510 | 451 | 350 | 400 |

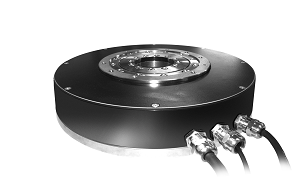

PDDR: HOUSED TORQUE MOTORS WITH PRECISION BEARINGS AS ROTARY TABLES WITH HOLLOW SHAFT

The torque motors of the PDDR torque motor series from our partner PBA are rotary direct drive servo motors, completely installed in the housing with a high-resolution encoder system (incremental or absolute (Biss-C, single turn) and precise bearings - basically they are direct drive rotary tables with a through bore (hollow shaft).

A special magnetic design results in high torques with low detent torque (cogging), making PDDR torque motors suitable for dynamic applications with high synchronisation requirements.

The advantages of the PDDR series direct drive rotary tables are:

- low cogging torque ensures smooth running at high and low speed

- very good controllability even at low speeds

- high repeatability and accuracy due to no gearing backlash, slippage or coupling compliance errors

- compact design due to high torque density

- excellent dynamic behaviour

- easy integration and installation

- high service live with no maintenance

The most important features of PDDR torque motors are:

- 6 sizes with diameters of 110mm, 150mm, 160mm, 240mm and 300mm

- several overall lengths of each flange size

- hollow shaft (through bore)

- various mounting options (optional flange)

- continuous torque from 2Nm to 400Nm

- peak torque from 6Nm to 1,090Nm

- sine encoder with optional interpolation (TTL encoder)

- overtemperature protection by built-in thermistor

- Hall effect sensors

nbsp]

New add-on version PDDR-B torque motors with BiSS-C Absolute Feedback:

- 6 sizes with diameters of 135mm, 175mm, 230mm, 290mm, 360mm und 380mm

- several overall lengths of each flange size

- hollow shaft (through bore)

- various mounting options (optional flange)

- continuous torque from 3 to 330Nm

- peak torque from 9 to 1.000Nm

- 20 bit BiSS-C-Absolute-Encoder (single-turn)

- overtemperature protection by built-in thermistor

Suitable Servodrives with CANopen, EtherCAT or ProfiNet can be found here:

- 3-phase 400 / 480Vac supply: Servo Controller Kollmorgen AKD / AKD2G

- 3-phase/1-phase 110Vac to 230Vac supply: Servo Controller Copley Xenus / Kollmorgen AKD / AKD2G

- DC-supply 12Vdc / 24Vdc / 48Vdc / 96Vdc / 180Vdc: Servo Controller Copley Argus / M-Series / IES / Accelnet Plus / Accelus and Kollmorgen AKD / AKD2G

| model | peak torque |

continuous torque (at 100°C) |

peak current |

continuous current |

torque constant |

back-EMF constant |

resistance (ph.-ph.) |

inductance (ph.-ph.) |

pole pairs |

max. voltage |

dimensions | hollow shaft |

rotor inertia |

mass |

continuous speed |

| Mp | Mc | Ip | Ic | KT | KE | Rph-ph (at 100°C) |

Lph-ph | V | Øxl | Ø | J | m | Sn | ||

| Nm | Nm | Adc | Aeff. | Nm/Apk. | Vdc/rad/sec | Ω | mH | Vdc | mm | mm | kg.cm² | kg | 1/min | ||

| PDDR110-06-I | 6.0 | 2.0 | 4.2 | 1.0 | 1.4 | 1.6 | 13.9 | 18.9 | 10 | 400 | 110x85 | 20 | 7 | 3.9 | 600 |

| PDDR110-12-I | 12.0 | 4.0 | 4.2 | 1.0 | 2.8 | 3.3 | 24.2 | 37.8 | 10 | 400 | 110x116 | 20 | 12 | 5.4 | 480 |

| PDDR150-T-I | 4.3 | 1.4 | 5.1 | 1.2 | 0.8 | 1.0 | 13.6 | 8.3 | 8 | 400 | 150x45 | 28 | 22.6 | 4.4 | 600 |

| PDDR150-15-O | 15.7 | 5.2 | 7.6 | 1.8 | 2.1 | 2.4 | 8.2 | 31.8 | 10 | 400 | 152x85 | 48 | 120 | 6.4 | 300 |

| PDDR150-30-O | 32.2 | 10.7 | 7.6 | 1.8 | 2.1 | 2.4 | 3.3 | 15.9 | 10 | 400 | 152x117 139 171 | 48 | 210 | 9.8 | 300 |

| PDDR150-50-O | 54.4 | 18.1 | 15.7 | 3.7 | 3.5 | 4.0 | 4.3 | 26.8 | 10 | 400 | 152x139 171 | 48 | 240 | 12.2 | 300 |

| PDDR150-80-O | 86.6 | 28.9 | 15.7 | 3.7 | 5.5 | 6.3 | 6.3 | 39.7 | 10 | 400 | 152x171 | 48 | 290 | 15.6 | 300 |

| PDDR160-40-I | 40 | 13.3 | 18.2 | 4.3 | 2.2 | 2.5 | 3.9 | 10.4 | 10 | 400 | 160x125 | 28 | 31 | 13.2 | 420 |

| PDDR160-80-I | 81 | 27 | 38.2 | 9.0 | 2.1 | 2.4 | 1.7 | 4.6 | 10 | 400 | 160x187 | 28 | 52 | 19.0 | 540 |

| PDDR240-30-I | 30.7 | 10.2 | 13.2 | 3.1 | 2.3 | 2.7 | 5.9 | 30 | 16 | 400 | 240x59 | 52 | 92 | 10.7 | 300 |

| PDDR240-80-I | 80.6 | 26.9 | 17.8 | 4.2 | 4.5 | 5.2 | 5.6 | 32 | 16 | 400 | 240x80 | 52 | 143 | 14.7 | 270 |

| PDDR240-132-I | 132 | 44.0 | 17.0 | 4.0 | 7.8 | 8.9 | 8.3 | 30 | 16 | 400 | 240x105 | 52 | 203 | 19.7 | 168 |

| PDDR300-150-I | 150.1 | 50.0 | 17.4 | 4.1 | 8.6 | 9.9 | 6.9 | 43.4 | 16 | 400 | 300 (340)x140 | 90 | 1.004 | 45 | 174 |

| PDDR300-300-I | 299.7 | 99.9 | 38.2 | 9.0 | 7.9 | 9.0 | 2.9 | 19.6 | 16 | 400 | 300 (340)x173 207 | 90 | 1.288 | 55 | 180 |

| PDDR300-450-I | 450.9 | 150.3 | 38.2 | 9.0 | 11.8 | 13.6 | 3.8 | 26.9 | 16 | 400 | 300 (340)x207 | 90 | 1.576 | 120 | |

| PDDR490-600-I | 540 | 200 | 49.6 | 10.5 | 13.4 | 15.5 | 2.3 | 19.4 | 24 | 400 | 490x95.5 107.5 126.5 | 125 | 5.360 | 80.2 | 168 |

| PDDR490-900-I | 780 | 300 | 49.6 | 10.5 | 23.3 | 15.5 | 2.9 | 28.8 | 24 | 400 | 490x107.5 | 125 | 6.310 | 91.5 | 114 |

| PDDR490-1200-I | 1.090 | 400 | 49.6 | 10.5 | 26.9 | 31.0 | 3.5 | 39.9 | 24 | 400 | 490x126.5 | 125 | 7.620 | 100.5 | 84 |

PRINT PAGE |

PRINT PAGE |