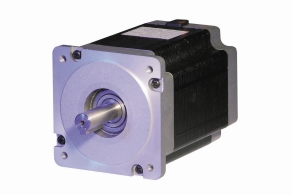

HIGHTORQUE HYBRID STEPPER MOTORS DSMH

The hybrid stepper motors of Geeplus' DSMH series are high-torque stepping motors with 1.8 degree full step angle motors for microstepping mode; due to optimized rotor form and new square lamination geometry, theDSMH step motors also have a very good efficiency. The DSMH stepper motor series comprises 7 flange sizes from 20mm to 110mm, each with several overall lengths. Audible noise generation has been minimized. These DSMH stepping motors are well suited for microstep operation.

The most important features of the DSMH Hightorque stepper motors are:

- high speed: The high torque hybrid stepper motors of the DSMH series enable high acceleration. By the choice of winding, high operating speeds can be achieved compared to conventional stepping motors (typically 30 to 50% higher)

- high torque: typically over 40% more torque than conventional stepper motors of the same size

- available in several flange sizes: Nema 8 (20mm), Nema 11 (28mm), Nema 14 (35mm), Nema 17 (42mm), Nema 23 (57mm), Nema 34 (86mm) and Nema 42 (110mm)

- high efficiency: the thin lamination and small air gap of the DSMH stepper motor series reduce electromagnetic losses to a minimum

- low noise and vibration: the square form and the high rigidity of the laminations plus the specially designed tooth geometry help the DSMH stepper motors to ensure minimum audible noise and vibration

- large shaft and bearing system: the DSMH series stepping motors include a heavy-duty shaft and large bearings assembly to allow for large side loads and axial forces

- winding connections: Most stepping motors of the DSMH family have 8 connections. This enables the 2 phase windings to be connected in any desired circuit in serial or parallel or in unipolar or bipolar arrangement

- winding for 12V (DC), 24V (DC) or 48V (DC)

- step angle 1.8° (0.9° on request)

- three-phase version on request

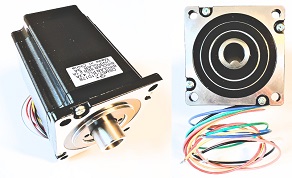

One possible modification is the machining of the shaft, e.g. versions of stepper motors with a hollow shaft are possible. One example is the DSM57-C10178, which is designed with a hollow shaft for a Nema 23 flange with 57x57mm. Make an enquiry!

New in the program are also stepper motors with encoder - an example is the DSMHE6069 with a 1000 line incremental encoder; evena an optional brake is possible. The "stepper motor with encoder" product range is being further expanded. The advantage of combining a hybrid stepper motor with an incremental or even absolute encoder is the high torque density at low speeds. In combination with an appropriate stepper motor controller, which can also operate the stepper motor in servo mode, this results in a cost-effective servo system with high torque from a compact mechanical package.

We suggest the Copley Stepnet Stepper Motor Drives for the DSM series stepper motors, especially the stepping motors with encoder feedback.

| type | winding resistance* Ohm |

winding inductance* mH |

nom. current* A |

continuous torque Nm |

cogging torque Nm |

rotor inertia kg.mm² |

mass kg |

lead length mm |

| DSM2030H-14060 | 6.5 | 1.7 | 0.6 | 0.06 | 450 | |||

| DSM2033H-14060 | 6.5 | 1.7 | 0.6 | 0.06 | 450 | |||

| DSM2832H-16065 | 2.8 | 1.0 | 0.65 | 0.06 | 0.9 | 0.11 | 300 | |

| DSM2845H-16065 | 3.4 | 1.2 | 0.65 | 0.09 | 1.2 | 0.14 | 300 | |

| DSM2851H-16065 | 4.6 | 1.4 | 0.65 | 0.11 | 1.8 | 0.20 | 300 | |

| DSM3526H-14080 | 4.0 | 2.3 | 0.80 | 0.05 | 1.0 | 0.15 | 300 | |

| DSM3526H-16040 | 4.0 | 2.3 | 0.40 | 0.05 | 1.0 | 0.15 | 300 | |

| DSM3536H-14100 | 2.8 | 1.00 | 0.10 | 300 | ||||

| DSM4234H-x4040 | 30.0 | 32 | 0.40 | 0.25 | 0.02 | 2.4 | 0.20 | 400 |

| DSM4234H-14150 | 1.3 | 1.3 | 1.50 | 0.21 | 0.02 | 2.4 | 0.20 | 400 |

| DSM4239H-14170 | 1.5 | 3.2 | 1.70 | 0.44 | 0.02 | 3.2 | 0.24 | 400 |

| DSM4248H-x8085 | 3.0 | 2.3 | 0.85 | 0.48 | 0.03 | 4.0 | 0.29 | 400 |

| DSM5741H-x8070 | 5.0 | 35 | 0.70 | 0.55 | 0.03 | 12 | 0.50 | 500 |

| DSM5750H-x8075 | 5.0 | 30 | 0.75 | 0.80 | 0.03 | 15 | 0.65 | 500 |

| DSM5755H-x8200 | 0.7 | 3.0 | 2.00 | 1.15 | 0.04 | 28 | 0.75 | 500 |

| DSM5776H-x8100 | 4.0 | 12.0 | 1.00 | 1.85 | 0.08 | 44 | 1.15 | 500 |

| DSM5776H-x8200 | 1.0 | 4.0 | 2.00 | 1.85 | 0.08 | 44 | 1.15 | 500 |

|

DSM57-C10178, Rev. 2 with hollow shaft 11mm |

1.0 | 2.2 | 2.00 | 3 | 0.068 | 48 | 1 | 305 |

| DSM57115H-18300 | 0.7 | 2.0 | 3.00 | 2.7 | 0.15 | 69 | 1.75 | 500 |

|

DSMHE6069-14500 Encoder 4000 counts per rev |

0.38 | 1.2 | 5.00 | 2.1 | 1.2 | 500 | ||

| DSM8665H-18220 | 1.50 | 4.1 | 2.20 | 2.9 | 100 | 2.0 | 300 | |

| DSM8680H-18275 | 0.95 | 4.0 | 2.75 | 4.5 | 140 | 2.3 | 300 | |

| DSM86118H-18300 | 1.40 | 7.4 | 3.00 | 8.5 | 270 | 3.8 | 300 | |

| DSM86156H-18310 | 1.70 | 9.7 | 3.10 | 12.0 | 400 | 5.4 | 300 | |

| DSM11099H-18275 | 0.90 | 12.5 | 2.75 | 11.5 | 550 | 5.0 | 500 | |

| DSM110150H-18325 | 0.72 | 12.8 | 3.25 | 21.0 | 1.090 | 8.4 | 500 |

HYBRID STEPPER MOTORS CT

The CT series hybrid stepper motors combine innovative cooling technology, a magnet design for high torque, robust bearings and high dielectric strength. These features ensure high torque output for heavy mechanical loads and enable use with all drives.

The outstanding performance is just one part of the CT Series' success story. The CE-certified motors are available in the common flange sizes (Nema17 (42mm), Nema23 (57mm) and Nema34 (86mm)) and in different lengths, with different windings and shafts.

The most important features of CT hybrid step motors are:

- winding for 12V (DC), 24V (DC) or 48V (DC)

- high-performance magnet design: large rotor diameter, small air gap and high-energy magnets as well as computer-controlled winding guarantee maximum torque at minimum volume

- housing designed for cooling: Aluminium jacket and aluminium end pieces dissipate the heat of the motor very quickly. In this way, higher current and torque ratings can be achieved, especially when the motor is flanged. CT motors generate the same torque at lower temperatures and therefore offer a longer life

- large bearing system: the CT series stepping motors have large bearings, therefore they allow large radial and axial forces

- high dielectric strength: Low susceptibility to faults, as there are no connections or gaps thanks to the stator enclosed by a moulded insulating insert. Higher reliability and voltage ratings. CT series motors can be used with all standard and high voltage/high power drives

- optional: digital incremental AquadB encoder

We suggest the Copley Stepnet Stepper Motor Drives for the DSM series stepper motors

TIN CAN PERMANENT MAGNET STEPPER MOTORS PF/PFC

The stepping motors of the PF/PFC series are tin can stepping motors that impress with their excellent cost and performance. They are available in different diameters (25mm to 55mm), step angles (3.75°, 7.5° and 15°), windings and magnetic materials. In addition, a wide range of options (flange sizes, shafts, gears) are offered to achieve great flexibility. Other customer-specific requirements can also be met on request. The PF(C) series is well suited for use in mass applications in medical equipment, as well as printers, fax machines, but also analytical equipment and industrial plants.

The most important features of PF / PFC stepper motors:

- winding for 5V (DC), 12V (DC), 24V (DC) or 48V (DC)

- good price/performance ratio

- great flexibility: sizes, windings, step angle, magnetic materials

- 2-phase

- optional: ball bearings, pinion, pulleys, connections

PDF Geeplus DSMH High Torque Hybrid Step Motors Catalogue

PDF Geeplus DSMH High Torque Hybrid Step Motors Catalogue

PRINT PAGE |

PRINT PAGE |