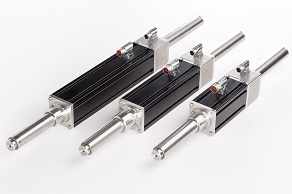

SERVOTUBE ELECTRIC CYLINDERS STA/XTA AS DIRECT DRIVE LINEAR SERVO ACTUATORS

The Servotube Linear Actuator is based on the Servotube linear motor - but here a sliding guide is integrated, so that the actuator can be operated directly without additional mounting of a guide. In this point the Servotube Linear Actuator is similar to a electric leadscrew cylinder or a pneumatic cylinder / pneumatic actuator.

The Servotube electric cylinder works physically like a conventional 3-phase brushless linear motor - however, in the Servotube electric cylinder the magnets are designed as a round rod which is guided through the inner hole of the winding. This results in a symmetrical structure that is free of lateral forces. A further advantage of this design is the closed version, which makes it possible to achieve protection class IP67.

The greatest advantage of the servo tube linear servo actuator is the integrated encoder: the magnets of the servo tube electric cylinder are scanned by precise hall-effect sensors and the position information obtained is converted into industrial 1Vpp signals that can be read in at the encoder input of the servo controller. This turns the Servotube electric cylinder into easy to handle and extremely low-cost linear servo actuators with which a repeatability of +/-8µm (depending on size) can be achieved.

For a ready plug & play solution we offer you the suitable controllers of the Xenus or Accelnet series (see Xenus or Accelnet servo drives). Those allows both stand-alone solutions (indexer operation or ASCII commands via RS-232 or I/O control) and fieldbus-controlled network solutions (CANopen or EtherCAT) to be implemented.

For other controllers that cannot read the low-frequency 1Vpp signals of the Servotube linear servo actuators, we offer an interpolation unit based on Copley's Accelnet ADP drive; with this unit the 1Vpp signals are interpolated and output as TTL AquadB encoder signals with a programmable resolution; in addition, digital hall-effects signals are emulated and the thermal contact can be output via the interpolator together with the other signals in one cable.

The main features of the Servotube STA/XTA series electric cylinders are:

- high force density: 7 to 276N continuous (46 to 1,860N peak)

- wide working range: 318mm stroke (depending on size)

- integrated measuring system (sine/cosine, 1 Vpp), optional interpolation module for AquadB encoder output

- high protection class: IP67 standard (optionally food grade)

- Plug & Play: ready-made motor files for the Xenus/Accelnet controller, cables etc. available

- direct drive electric cylinder: dynamic, precise, backlash-free, quiet, maintenance-free, long life

PDF Servotube Linear Servo Actuator Application Examples

PDF Servotube Linear Servo Actuator Application Examples PDF Servotube Linear Servo Actuator STA11 Data Sheet

PDF Servotube Linear Servo Actuator STA11 Data Sheet PDF Servotube Linear Servo Actuator STA25 Data Sheet

PDF Servotube Linear Servo Actuator STA25 Data Sheet PDF Servotube Linear Servo Actuator XTR25 Data Sheet

PDF Servotube Linear Servo Actuator XTR25 Data Sheet PDF Brake for Servotube Linear Servo Actuator STA25 Data Sheet

PDF Brake for Servotube Linear Servo Actuator STA25 Data Sheet PDF Servotube Linear Servo Actuator XTA38 Data Sheet

PDF Servotube Linear Servo Actuator XTA38 Data Sheet PDF Servotube Linear Servo Actuator STA11 Installation Guide

PDF Servotube Linear Servo Actuator STA11 Installation Guide PDF Servotube Linear Servo Actuator STA25 Installation Guide

PDF Servotube Linear Servo Actuator STA25 Installation Guide PDF Servotube Linear Servo Actuator XTR25 Installation Guide

PDF Servotube Linear Servo Actuator XTR25 Installation Guide PDF Servotube Linear Servo Actuator XTA38 Installation Guide

PDF Servotube Linear Servo Actuator XTA38 Installation Guide PDF Servotube Linear Servo Actuator General Mounting Instructions

PDF Servotube Linear Servo Actuator General Mounting Instructions

| model | 1104 | 1108 | 1112 | 1116 | 2504 | 2506 | 2508 | 2510 | 3804 | 3806 | 3808 | 3810 |

| continuous force without heat sink N |

6 | 10.8 | 15.2 | 19.3 | 42.5 | 59.5 | 75.1 | 90.0 | 120.1 | 168.2 | 212.7 | 255.0 |

| peak force N |

46 | 53 | 69 | 92 | 312 | 468 | 624 | 780 | 744 | 1116 | 1488 | 1860 |

| max. speed m/s |

5.3 | 5.6 | 5.4 | 4.7 | 5.9 | 5.3 | 4.7 | 4.2 | 4.7 | 3.8 | 3.1 | 2.6 |

| max. acceleration m/s^2 |

407 | 359 | 378 | 422 | 394 | 483 | 542 | 586 | 250 | 313 | 357 | 391 |

| stroke (actuator) mm |

14 - 271 | 27 - 309 | 33 - 318 | |||||||||

| forcer w x h mm |

61 x 28 | 68+27 x 54 | 84+38 x 70 | |||||||||

| forcer length mm |

124.1 | 175.3 | 226.5 | 277.4 | 188.5 | 239.5 | 290.5 | 341.5 | 258.0 | 329.0 | 400.0 | 471.0 |

| Forcer mass kg |

0.240 | 0.390 | 0.520 | 0.650 | 1.25 | 1.70 | 2.25 | 2.65 | 2.75 | 3.75 | 4.75 | 5.75 |

| shaft diameter mm |

11 | 25 | 38 | |||||||||

| shaft mass kg/m |

0.68 | 3.5 | 8.3 | |||||||||

SERVOTUBE LINEAR ACTUATORS SL38 SERIES AS DIRECT DRIVE FOR 3x400Vac

In response to many customer requests, the previous Servotube linear actuators were also developed for the higher industrial voltage 3x400Vac (560Vdc DC link voltage). Drivers for this development were the compatibility to further servo amplifiers and a higher force. As with the previous Servotube linear actuators, the sliding guide is integrated in these new linear direct actuators, so that this electric cylinder can be operated directly without additional installation of a guide. In this respect, the Servotube linear actuator is therefore similar to a spindle actuator (electric actuator) or a pneumatic cylinder / pneumatic actuator. In the new development, the outer diameter of the push rod was retained at 38mm, but the design of the motors was fundamentally redesigned in order to be able to meet the collected customer requirements; for the higher force, for example, the use of more and higher-quality permanent magnets was necessary. As a result, a significantly higher continuous and peak force can now be offered - even water cooling is prepared.

The main features of the SA/SC series servotube linear actuators are:

- three sizes: 3806/3810/3814

- high force density: 140 to 308N (with water cooling 616N) continuous (1581 to 3690N peak)

- wide working range: up to 456mm

- integrated measuring system (sine/cosine, 1 Vpp, 12.5 mciron resolution), BiSS/SSI/RS422 in preparation

- high protection class: IP65

- rotatable motor plugs

- maintenance-free plain bearing

- direct drive: dynamic, precise, backlash-free, quiet, maintenance-free

- alternatively version as linear motor available (components stator / magnet track without bearing)

| model | 3806 | 3810 | 3814 | |||

| nominal voltage VDC |

325 | 560 | 325 | 560 | 325 | 560 |

| continuous force without cooling N |

140 | 226 | 308 | |||

| continuous force with water cooling N |

279 | 452 | 615 | |||

| peak force N |

1581 | 2285 | 2637 | 2214 | 3690 | |

| max. velocity m/s |

3.8 | 6.3 | 2.7 | 4.4 | 2 | 3.4 |

| max. acceleration m/s^2 |

>200 | |||||

| stroke (actuator) mm |

up to 456 | |||||

| forcer w x h mm |

80 x 80 | |||||

| forcer length mm |

325.8 | 428.2 | 530.6 | |||

| forcer mass kg |

3.0 | 5.0 | 7.2 | |||

| shaft diameter mm |

38 | |||||

| shaft mass kg/m |

8.3 | |||||

PRINT PAGE |

PRINT PAGE |